Robots

Industrial collaborative robots are used to automate the manufacturing process almost entirely without human help on the manufacturing floor. They help remove operators from unsafe environments and free up an employees time for other tasks within a facility. They are faster, have higher payloads, therefore helping with heavier, dangerous and repetitive applications. Parts assembly, palletizing, and pick-and-place are common applications that Industrial robots can be used for.

These industrial collaborative robots (cobots) can assist a human operator and is typically used in applications working alongside human operators. Many cobots are designed with detection features that allow them operate in the same enviroment as humans, and are able to immobilize with the slightest touch preventing injuries. Collaborative robots are very easy to program and are capable of learning quickly. They can easily be moved and used in different areas of production.

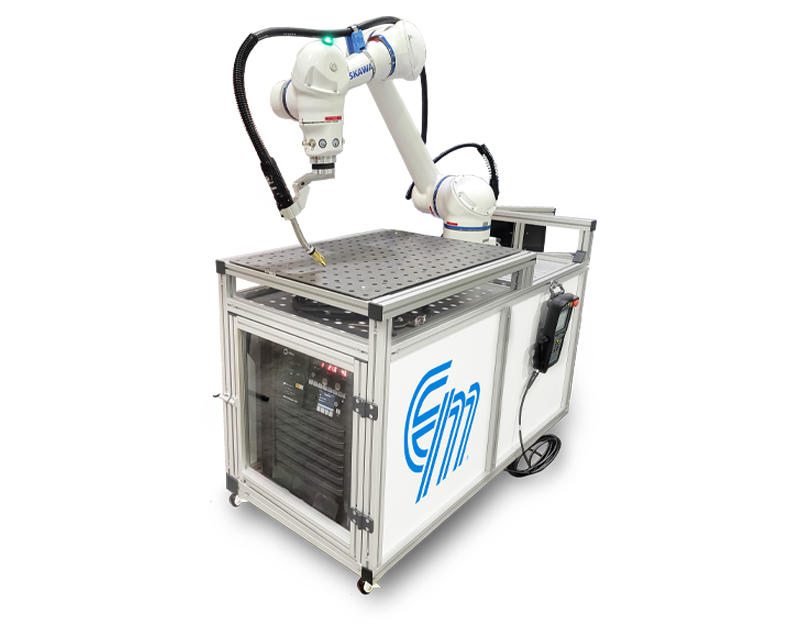

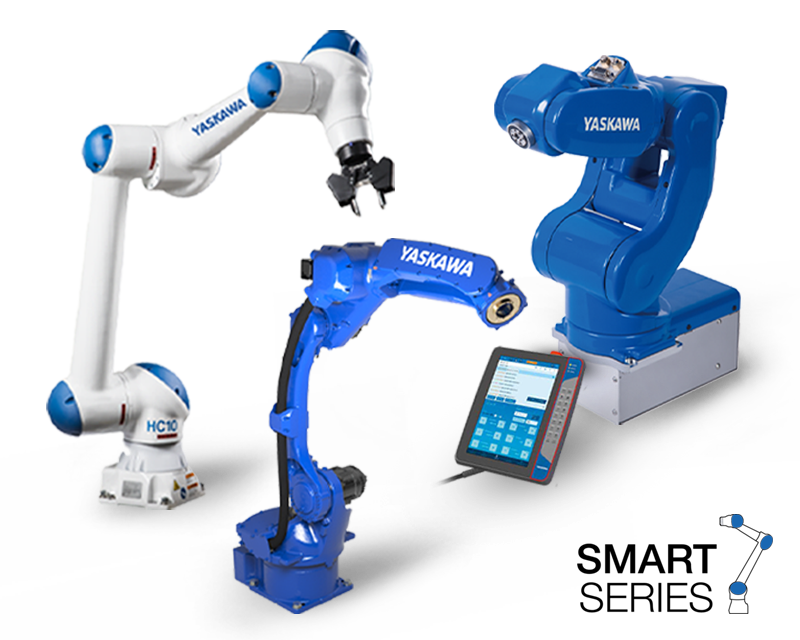

Yaskawa Motoman’s, high-speed industrial collaborative robots include all of the aforementioned advantages of these types of robots. High-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots. In addition, with Yaskawa’s leading-edge controllers, vision systems, peripherals and other best-in-class components, Electro-Matic can help configure a solution tailored for your manufacturing needs.

HC10 Robot

The Yaskawa HC10 (Human Collaborative) robot is capable, affordable, versatile, easy to use and built with the industrial strength for more demanding applications. These robots are made for customers looking for easy automation, which will allow an industrial robot to automate tasks that require it to work in close proximity to humans.

HC20XP

Easy-to-Clean Collaborative Robot with Hand-Guided Teaching

Ideal for a variety of tasks, the robust six-axis HC20XP collaborative robot provides precise hand-guided teaching for fast implementation of a robot system. Offering four modes of collaborative operation such as Power and Force Limiting (PFL) technology, the HC20XP meets established safety standards, enabling humans to work with or in close placement to robots. Depending on risk assessment, this cobot can operate without extra safety features, saving space and lowering cost.

A through-arm Category 6 cable facilitates a wide selection of communication options for tooling, and an IP67 rating and easy-to-clean surface enables use in sanitary environments. The HC20XP also includes NSF H1 food-grade grease for use in spaces where there is the possibility of incidental food contact.

The HC20XP is compatible with the YRC1000 and YRC1000micro robot controllers.

The CASE for Collaboration

CAPABLE

Improves Production Rate

- Industrial-grade payload and speed for real world applications

- Can be used in a wide variety of handling and assembly applications

- Easily integrated into factory automation systems using discrete I/O or fieldbus networks such as Ethernet/IP

AFFORDABLE

Quickly Achieves ROI

- Reduced physical guarding

- Simplified, built-in networked safety I/O

- Built on Yaskawa legacy of quality and reliability

SAFE

Reduces Risk

- Advanced pinchless geometry

- Innovative thru-arm utilities

- Power and force limiting with FSU (Functional Safety Unit)

EASY

Empowers Employees

- Teach by hand guiding

- Quick fault recovery

- Simplifies basic training needs

Key Benefits

- Enables humans to safely work with robots

- Thru-arm utilities eliminate external cables and associated risks, and simplify end-of-arm tooling installation

- Cast aluminum construction for industrial durability

- Designed to avoid pinch points, increasing worker safety

- Easy teaching for quick implementation

- Can reach full, 80-inch tall pallets without an elevator

Motomini Small Robot

The MotoMini is the smallest and lightest 6-axis robot in the industry, and is 20% faster than comparable small robots. The internal cabling and air lines in the MotoMini series assist in minimizing interference with other process equipment, and with a variety of mounting options (surface, wall, ceiling, etc.) this helps accommodate high-density factory layouts.

Designed for extremely high-speed performance and suitable for a wide range of applications, the quiet, compact and precise MotoMini can take your small-part process to the next level.

GP Industrial Robot Series

Designed for fast-paced assembly, packaging and general handling processes, the GP-series robots deliver optimal speed, accuracy and range of movement, with each model offering a high wrist allowable movement, making accurate and repeatable handling possible. The superior speed of this robot family has a simple, space-efficient design, and is engineered for easy installation, operation and maintenance.

With Yaskawa’s leading-edge controllers, vision systems, peripherals and other best-in-class components, Electro-Matic can help configure a solution tailored for your manufacturing needs.

Start a Conversation

Have a question, need help with where to start, or want to get a quote? Fill out the form and one of our industrial robot experts will be in touch.