Identification and Locating

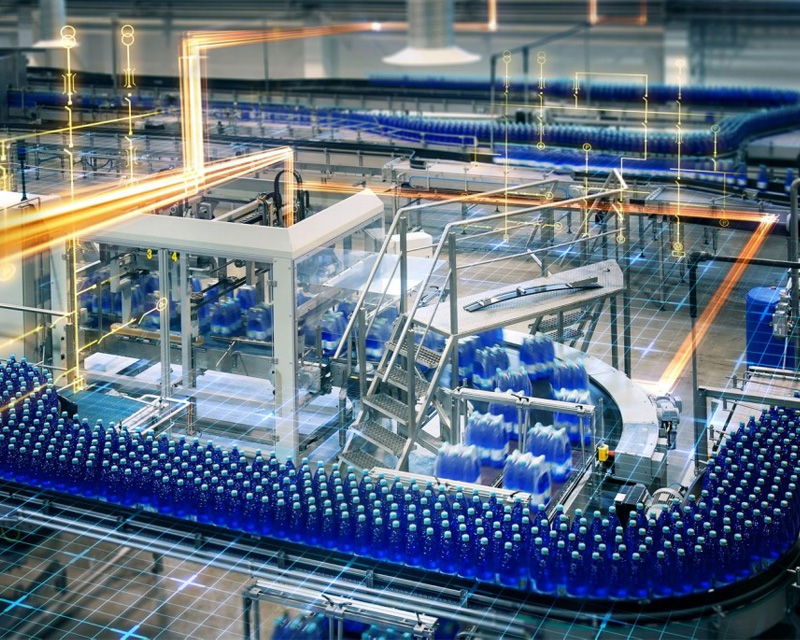

Industrial Identification and Real-Time Locating Systems (RTLS) are becoming a key technology for the Digital Enterprise. Siemens has complete solutions to create the potential to add value and create transparency along the entire production and supply chain. This helps companies respond faster and more efficiently to customer requests and market demands, while simultaneously improving quality.

Industrial Identification and Real-Time Locating Systems (RTLS) are becoming a key technology for the Digital Enterprise. Siemens has complete solutions to create the potential to add value and create transparency along the entire production and supply chain. This helps companies respond faster and more efficiently to customer requests and market demands, while simultaneously improving quality.

Used to automatically identify and track the location of anything from a vehicle to an item in a manufacturing plant to a person.

Siemens RFID Systems

Siemens RFID Systems make an entire production and supply chain visible by having the capability to monitor material flows at all times.

Siemens Optical Identification Systems

Reliable, flexible reading and verification of 1D/2D codes, with stationary or handheld readers, text recognition (OCR) and object recognition.

Are your assets and employees managed efficiently? Do you achieve enhanced productivity and operational efficiency?

Siemens’ solutions for industrial identification and locating have been successfully proven to help manufacturers operate more efficiently. As rising competition pushes organizations to look for viable ways to sustain profitability, technology advancements like RTLS have allowed for greater visibility into the overall production process, thus maximizing efficiency.

Food and Beverage

RTLS enables advances in Food and Beverage that are vital to the future of the industry

Know what’s where and when. Seamless, automated, and contactless locating systems create improvements throughout production and supply chains. Manual work steps are reduced, potential sources of error identified and avoided, and plant uptime is improved. Even with high levels of product customization, you will see a reduction in production time. Overall, you benefit from greater efficiency and flexibility in logistics, material management, production, and service across every application.

- Food safety

- Employee safety

- Factory performance and profitability

- Recipe process monitoring

- Container management

Automotive

We understand the main drivers of car manufacturers: time, quality and cost

Processes like the details of material handling, tracking and timing storage processes, quick access to the right equipment, effective Work in Progress and can make or break your production process. What if you could manufacture more cars, optimize your supply and process chain, receive more transparency while providing the highest level of quality and employee safety? Let us help you to take your production to the next level with our real-time locating solutions.

- Track assets and manage your warehouse effectively

- Manage and optimize Work in Progress (WIP)

- Track and control motorized vehicle and tools in your facility

- Ensure product quality and safety

- Keep your employees safe and your plant open

Interested in these products?

24/7 Technical Support

Electro-Matic offers around-the-clock technical support bolstered with a detailed knowledgebase, training videos, downloadable documentation and more.

Technical Training

Electro-Matic offers technical training sessions across Michigan and Ohio. Check out our Training Schedule for a list of upcoming sessions available near you.